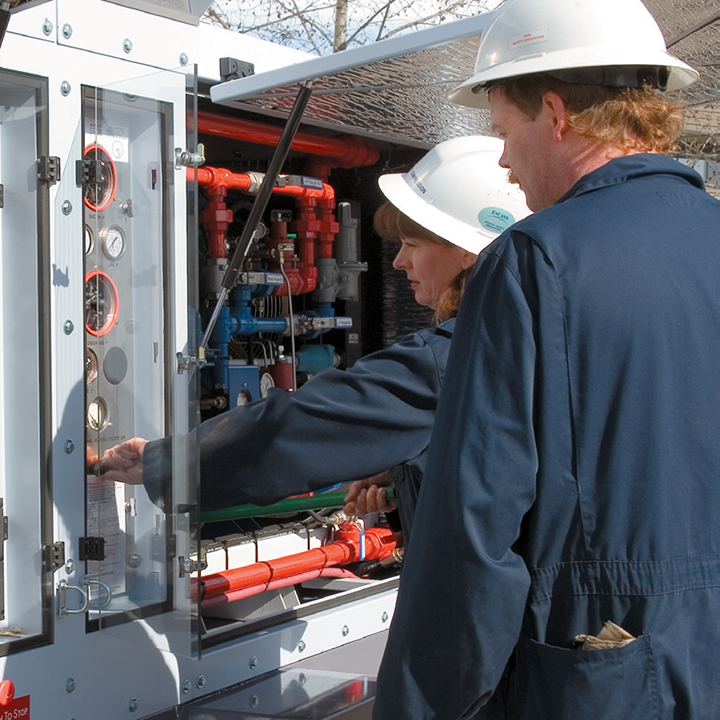

Preventive Maintenance | Scheduled Site Visits | Upgrades | Detailed Maintenance Records | 24/7 On-Call Service | OEM Parts

Our Goal:

Reduce your cost of ownership

How?

Less downtime due to failuresInspection Program – We use a model specific checklist which is continuously updated based on experience.

Upgrade Program – When widespread issues are found, affecting performance and durability, an engineered solution is developed to remove that problem.

Help Line – We have over the phone support for operators. This allows us to properly diagnose the problem so the mechanic going to site knows what to fix immediately. We also can advise the operator how to fix or keep the unit running until we can get on site.

Lower cost to repair

Troubleshooting skills – We diagnose the problem the first time. All service mechanics must go through a one month training program. They are also tied directly to the engineering department.

Troubleshooting skills – We diagnose the problem the first time. All service mechanics must go through a one month training program. They are also tied directly to the engineering department.

Do work faster – we have the most experience with our product.

Stocked parts - Parts that aren’t on the truck are usually large and will be carried if that is the suspected problem.

No excessive markup on parts – remove the middleman.

Production optimization

Our mechanics work directly with our engineering department to optimize the performance of the compressor.

No Hassle Service Plan - NHSP

Providing solutions for increased oil production with predictable service cost and No Hassle

What is the No Hassle Service Plan?

The NHSP is an all-inclusive fixed cost service plan for Hydraulic Casing Gas compressors (HCGs).

Why we offer a No Hassle Service Plan?

Our core business is casing gas compressors – design, build and service. The size of the Casing Gas Compression market is driven by economics, therefore lower capital and op cost, along with less hassle, results in a larger market. We realized that in order to grow the market, in addition to a new compression element, a new approach to service was needed – the No Hassle Service Plan and SkyView monitoring system. We see all unusual process and operational issues affecting reliability and service cost, and design and implement hardware and processes to minimize or eliminate their negative effects. The result, lower costs and less hassle leads to more sales.

How can our customers benefit from the NHSP?

|

Maximize Uptime |

Our customers benefit from increased oil production at minimal cost and No Hassle |

|

What does the all-inclusive No Hassle Service Plan actually include?

Service |

All compressor parts, fluids and labour for routine service, repair, and overhauls |

Monitoring |

SkyView, our reporting system, identifies and collects data from HCGs, allowing us to diagnose and avert potential interruptions before they occur. Customers can access live performance data through secure server |

Upgrades |

If there are endemic operational or service issues, we design these imperfections out and implement upgrades across the existing fleet. |

Travel |

Travel time and mileage to our established service areas (Calgary, Grande Prairie, Swift Current and Stoughton). Outside our regular service areas, a low fixed annual Remote Surcharge is applied; which presumes help from the customer for simple tasks. If required, we will have a Service Tech on site the next working day. |

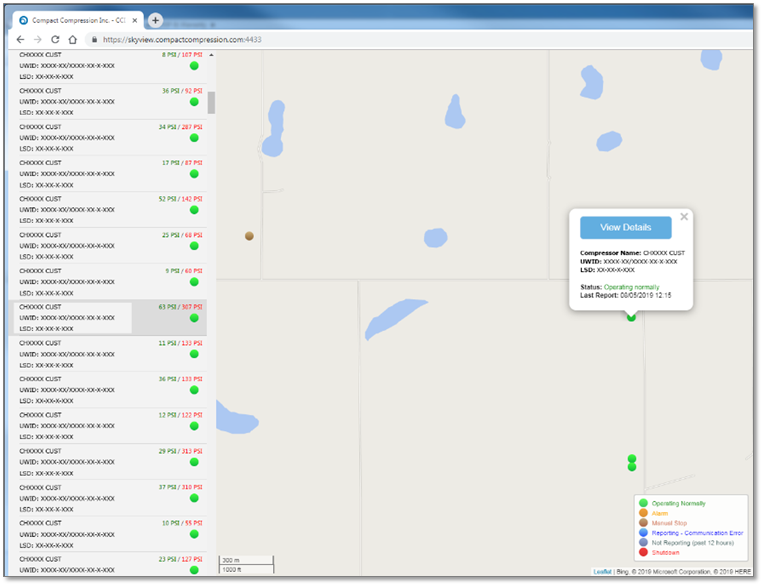

SkyView - Live Monitoring

24/7 Exclusive Access to Compressor Status - only available with our No Hassle Service Plan

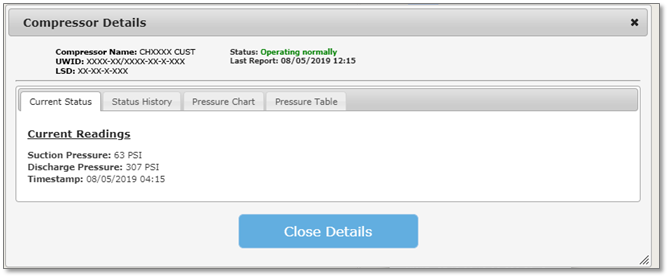

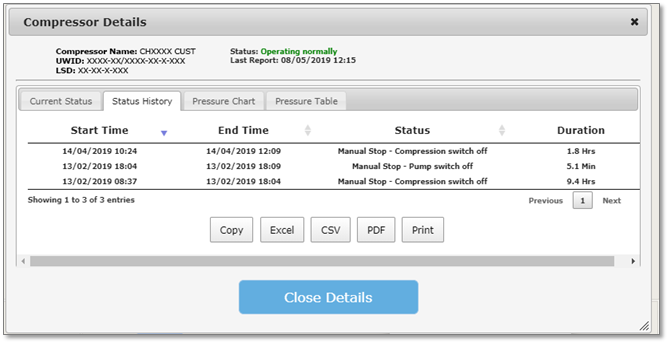

In 2018, CCI implemented SkyView, an IoT Platform that links HCG sensors, telemetry and a front-end so that HCG condition can be accessed on any internet capable device. SkyView is used as a predictive planning tool by field service technicians and dramatically shortens the response time to remedy distressed units. Additionally, customers have access to SkyView that can help optimize well performance.

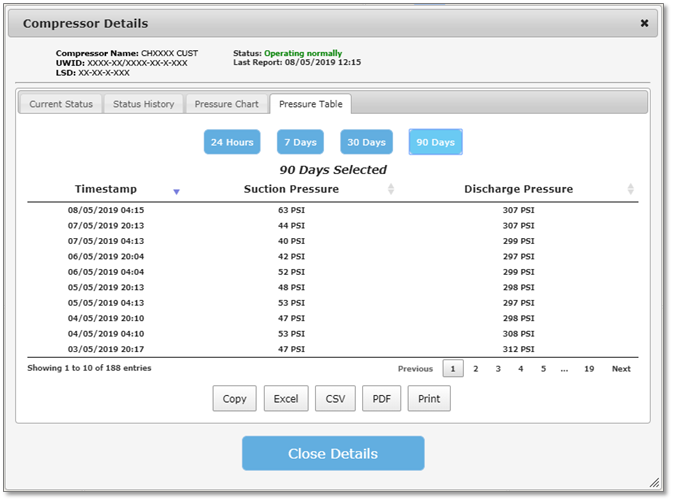

As a result of customer feedback and our own experience, we continue to make changes to the SkyView system to improve capabilities and ease of use. Having live status, suction and discharge pressure data available online eliminates operators making daily trips to wells to record pressure readings, increasing their efficient use of time and reducing driving exposure.

Used by CCI service technicians to:

- Diagnose and avert potential issues

- Maximize equipment uptime

- Reduce costs due to unnecessary visits

- Reduce costs due to catastrophic failure

Used by customers to:

- Monitor equipment status

- Monitor current compressor pressures and trends

An overview of compressor status in field

View all suction and discharge pressures at a single glance. With just a single click, access detailed information.

Access up to a 90-day snapshot of the compressor's pressure performance

Service Locations

Service locations conveniently located throughout the prairies.

Field Service Technicians

Southern Alberta

Jason Huntley

Cell: 1-403-975-8602

jhuntley@compactcompression.com

Lee Stevens

Cell: 1-403-826-4231

lstevens@compactcompression.com

Northern Alberta

Jason Huntley

Cell: 1-403-975-8602

jhuntley@compactcompression.com

Northern Alberta / British Columbia

Jamie Best (Grande Prairie)

Cell: 1-780-903-5960

mtranberg@compactcompression.com

Rylind Smith (Grande Prairie)

Cell: 1-403-899-3291

mtranberg@compactcompression.com

Saskatchewan (SW)

Jonathan Farewell

Cell: 1-306-294-7237

jfarewell@compactcompression.com

Saskatchewan (SW)

Tyler Boiteau

Cell: 1-306-750-6005

tboiteau@compactcompression.com

Saskatchewan (SE) / Manitoba

Chris Carlson

Cell: 1-306-421-6420

ccarlson@compactcompression.com

Robert Carlson

Cell: 1-306-897-5060

rcarlson@compactcompression.com

Vince Gilroy

Cell: 1-306-421-2716

vgilroy@compactcompression.com

Mike Swanson

Cell: 1-306-897-5003

mswanson@compactcompression.com