Initially designed for Casing Gas Compression, our equipment is often used in a variety of other operations:

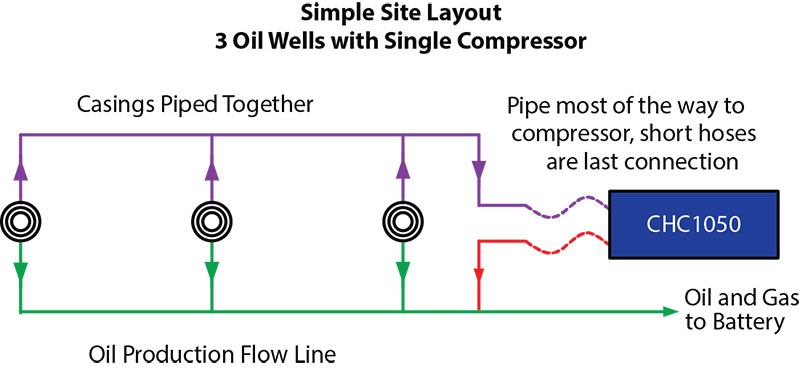

- Casing Gas Compression (Sweet & Sour Service)

- Wellhead/Field Production Optimization

- Multiphase Fluid Transfer

- Group Emulsion Header Boosting

- Poor Boy Gas Lift

- Pigging

- NG Boosting

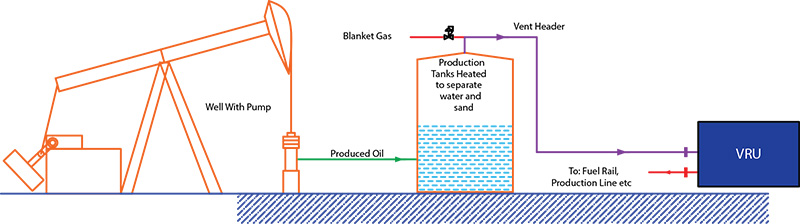

- Vapor Recovery

- Gas Pipeline Evacuation, Decommissioning, Maintenance and Repair

- Inline Inspections

- MAOP Testing

- Pressure Boosting

Casing Gas

Typical operating conditions:

- Suction pressure 15-40 psi (100-275 kPa)

- Discharge pressure 150-400 psi (1000-2800 kPa)

- Water saturated gas stream

- Mostly methane, with some longer chain hydrocarbons

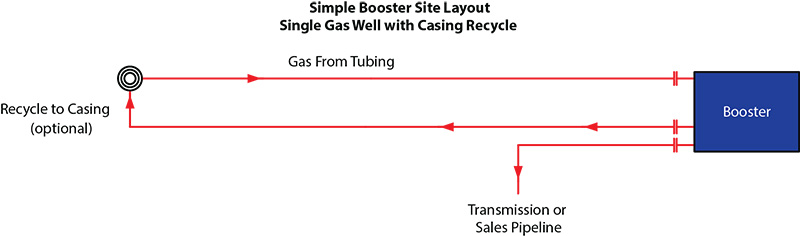

Gas Well Boosting

Typical Operating Conditions

- 0-50 Psi suction, 60-300 psi discharge

- Gas stream is primarily saturated methane, may have some sour content

Vapor Recovery

Typical Operating Conditions

- 0-1 psi (0-7 kPa) suction, 40-150 psi (275-1000 kPa) discharge

- High CO2 content, frequently some H2S content

- Water saturated gas stream

- Large range of hydrocarbons, short chain, long chain, solids