Processes gas fractions 0-100% | Easily Field Serviceable | Wide range of API gravity & viscosity | SkyView Reporting | Set & Forget PLC Control

Compact Compression’s Multiphase Transfer Pump (MPTP) is directly descended from the ground-breaking HCG Compressor, several of which have been employed in multiphase pumping service. Its principle of operation is very similar to the HCG Compressor with several key enhancements to product design and materials to increase performance, reliability and serviceability for multiphase pumping applications.

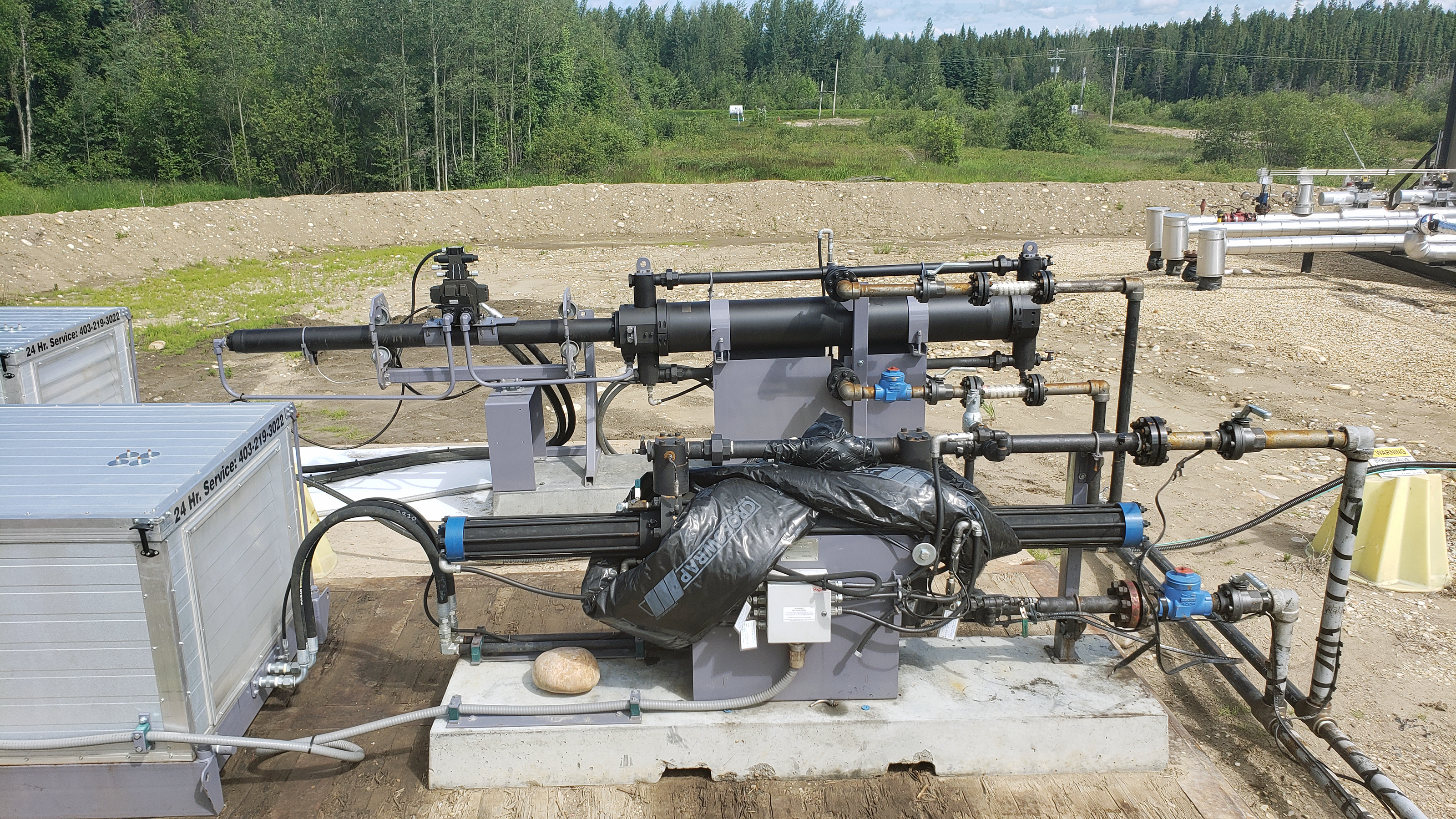

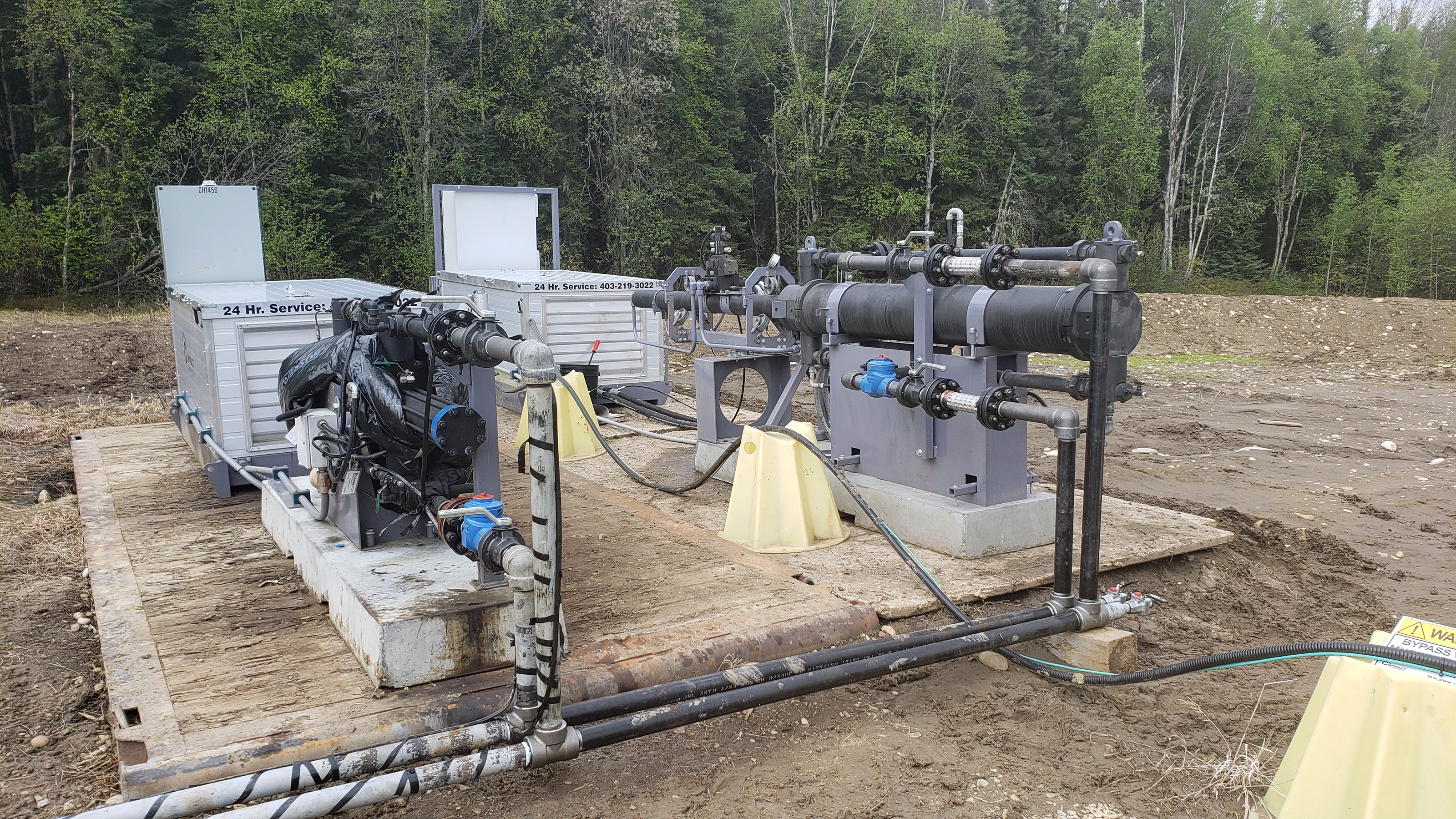

The MPTP is specifically designed for use at a satellite or header where production from multiple wells is collected. The resulting drop in line pressure allows the wells feeding into the MPTP to produce more.

The MPTP costs less than installing individual compressors on each well, has more throughput with less peak power demand and has a lower service cost than an HCG Compressor in multiphase service.

Separate pumps, compressors, separators, flares and process control systems at satellites can be eliminated with the MPTP. It can replace aging and maintenance intensive field infrastructure, reducing field OPEX. Lead times for new equipment, turnaround time for repairs and maintenance, capital costs and operating expenses are an order of magnitude less compared to typical twin-screw multiphase pumping systems.

Standard Features

- Capable of 100% liquid fractions instantaneously

- Average liquid rates up to 887 m3/d (5,577 bpd), 30% swept volume

- Maximum ∆P up to 2415 kPa (350 psi)

- Handles wide range of API gravity & viscosity

- 100% turndown capability

- No minimum liquid volume required through pump

- Highly tolerant of entrained solids

- Extremely robust intake and discharge valve design

- Optimized power utilization

- Seals can be easily replaced on site

- No additional lifting equipment required for servicing

- Superior user interface – web browser HMI

Benefits

- Decreases flowline pressure at wellhead

- Reduces head and power requirements for downhole pumps

- Eliminates the need for separate pumps and compressors at satellite facilities

- Eliminates flaring from separator vessels at satellites

- Low capital and operating cost

- Very quick turnaround for repair and maintenance

| Motor | 50 hp |

| Operating Pressure Range | Upto 1500 psi |

| Maximum Differential Pressure | 350 psi |

| Average Liquid Flow Range | 5,577 bpd |

| Gas Flow Range | 0 - 1367 mscfd |

| MPTP Weight | 3,200 lbs/1,452 kgs |

| Power Pack Weight (Electric) | 2,750 lbs/1,247 kgs |

| MPTP Dimensions | Length: 172"/4.37m Width: 25"/0.63m Height: 56"/1.42m |

| Power Pack Dimensions (Electric) | Length: 103"/2.62m Width: 53"/1.35m Height: 78"/1.98m |

| Multiphase Fluid Transfer |

| Group Emulsion Header Boosting |

| Field Production Optimization |

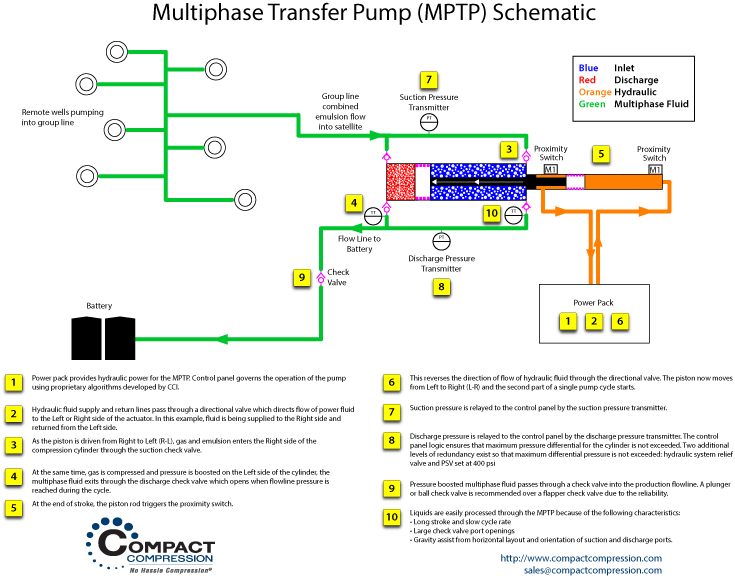

MPTP Schematic

*Information is provided as a guideline only, contact CCI for exact layout. (Click schematic to download)

Performance

MPTP 50hp Motor - Projected Performance

| DISCHARGE PRESSURE (psig/kPag) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

SUCTION(psig/kPag) |

PSI kPa |

100 700 |

150 1035 |

200 1380 |

250 1725 |

300 2070 |

350 2420 |

400 2760 |

450 3100 |

500 3450 |

| 10 70 |

133 3.8 |

123 3.5 |

93 2.6 |

70 2.0 |

53 1.5 |

48 1.4 |

||||

| 20 140 |

198 5.6 |

187 5.3 |

144 4.1 |

112 3.2 |

86 2.4 |

81 2.3 |

||||

| 30 210 |

265 7.5 |

254 7.2 |

227 6.4 |

179 5.1 |

144 4.1 |

113 3.2 |

||||

| 40 280 |

331 9.4 |

322 9.1 |

290 8.2 |

230 6.5 |

183 5.2 |

145 4.1 |

||||

| 50 345 |

397 11.2 |

389 11.0 |

357 10.1 |

279 7.9 |

233 6.6 |

178 5.1 |

||||

| 75 520 |

563 15.9 |

554 15.7 |

536 15.1 |

420 11.9 |

332 9.4 |

263 7.5 |

247 7.0 |

|||

| 100 700 |

720 20.3 |

711 20.1 |

643 18.2 |

510 14.4 |

411 11.6 |

334 9.4 |

312 8.8 |

|||

| 150 1035 |

1044 29.5 |

1034 29.2 |

931 26.3 |

732 20.7 |

595 16.8 |

486 13.7 |

450 12.7 |

|||

| 200 1380 |

1367 38.6 |

1358 38.4 |

1204 34.0 |

952 26.9 |

777 22.0 |

637 18.0 |

||||

| Projected Performance based on 2500 ft, gas density .665, temp 68ºF – Flow Rates in mscfd e3m3/day Table values based on 100% gas fillage. Liquids volume reduces gas throughput proportionally as a percentage of swept volume | ||||||||||

| Swept Volume | ||||

|---|---|---|---|---|

| Hyd. Pump | Maximum Flow | Maximum ΔP | ||

| Pressure Range | m3/d | bpd | psi | kPa |

| Very High | 1360 | 8550 | 350 | 2413 |

| High | 1750 | 11,010 | 270 | 1861 |

| Medium | 2180 | 13,710 | 220 | 1517 |

| Low | 2660 | 16,730 | 170 | 1172 |